Colloquium announcement

Faculty of Engineering Technology

Department Production Technology (MS3)

Master programme Mechanical Engineering

As part of his / her master assignment

Braakhuis, A. (Allard)

will hold a speech entitled:

An optimisation algorithm for problems with heavy black box constraints using sequential improved RBF-surrogate modeling

| Date | 13-04-2023 |

| Time | 13:30 |

| Room | HT 500B |

Summary

In engineering, finding an optimal design is often important, particularly when weight or cost should be minimised. However, the designs should often meet constraints and finding an optimal design that meets these constraints is not always straightforward. An example of a difficult optimisation problem is the design for the overmoulding of thermoplastic composites, a process where plastic features such as ribs are moulded onto a continuous fibre reinforced thermoplastic composite laminate. Usually finite element analysis (FEA) software is used to calculate whether a design meets the constraints. These calculations are computationally heavy and offer no insight in the mathematical or physical behaviour governing the constraint, so called black-box constraints. This research proposes a method to deal with such problems. In particular optimisation problems that have a simple objective function but computationally heavy black box constraints, using as few evaluations as possible.

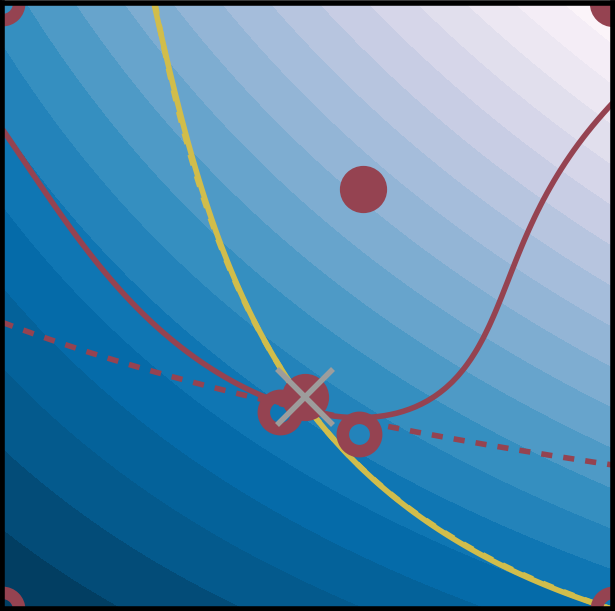

The method proposed in this research is based on surrogate modelling of the constraints. This is the process of setting up a mathematical prediction based on a set of evaluated designs. These surrogate models, or response surfaces, can be used to estimate the value of constraints throughout the whole domain. Based on this it can be estimated whether a specific design will satisfy the constraints or not. Next to this, an uncertainty model is introduced such that a probability of meeting a constraint can be provided, rather than only predicting whether a design will meet the constraints or not. Based on the surrogate models for the constraints and their uncertainty models, a design is chosen that has a better objective function value than previously evaluated points, while it is expected that it will still comply with all constraints. This design is evaluated, and the evaluated values are used to update the surrogate models. This process iterates until no better design can be found or the maximum amount of iterations is reached. Because the surrogate models describe the complete design space, the algorithm is likely to find a global optimum instead of converging to a local optimum.

The algorithm has been applied to a case study that is a simplified representation of the overmoulding design problem. For this case, generally with only 8 to 10 design evaluations a design near the theoretical optimum could be found. Because of this, the algorithm is considered promising for problems where heavy black-box constraints make up most of the computational time.

Assessment committee |

chair Signature d.d. |

|

| Ton Bor Wouter Grouve Jos Havinga Erik Krämer Elizaveta Karaseva |

(chair) (supervisor) (external member) (mentor from company) (internal member) |

|