Colloquium announcement

Faculty of Engineering Technology

Department Applied Mechanics & Data Analysis (MS3)

Master programme Mechanical Engineering

As part of his / her master assignment

Gonzalez Camacho, L.F. (Luis)

will hold a speech entitled:

Towards a robust in-situ AFP process: Quantifying the effect of surface consolidation state

| Date | 06-07-2023 |

| Time | 14:00 |

| Room | OH115 |

Summary

Fiber reinforced thermoplastic composites have gained much popularity in recent years. Their high performance and lightweight make them attractive materials for the aerospace industry. In addition, their melt/solidification capabilities enable the use of advanced technologies for high volume production and manufacturing of complex parts. One such technology is the laser-assisted tape placement process (LATP).

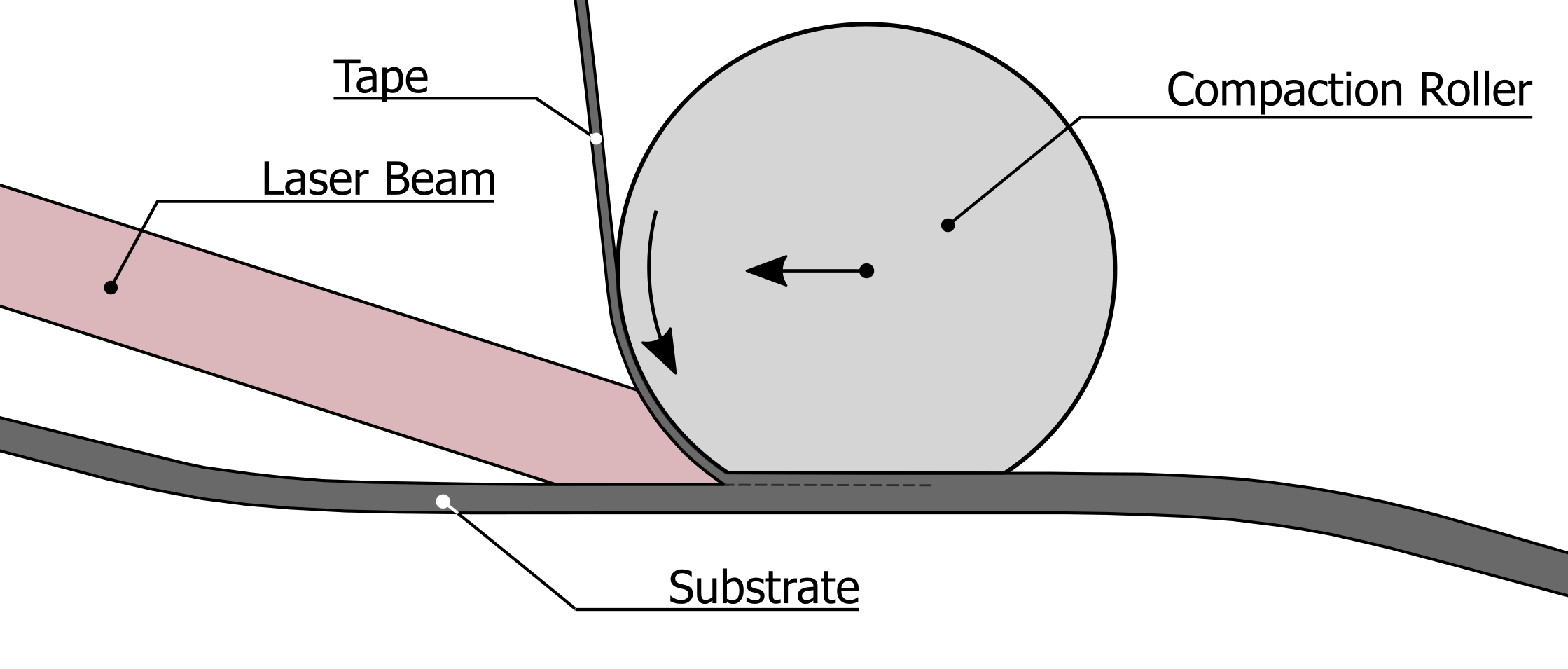

The LATP process uses UD carbon fiber together with laser heating and compaction to bond and place the material. When the final consolidation happens during the process, it is referred to as in-situ consolidation (ISC) and has the potential to build complex composite parts through a single step process. However, the effects of the process parameters and the surface quality of the incoming process zone are not completely understood. Efforts to find and optimize the placement parameters require expensive trial and error. Thus, a process window for an ISC with LATP process is necessary.

The challenge lies in quantifying and studying the effects of surface composition near the process zone on the temperature response. As well as how these affect interlaminar fracture toughness. The aim of the present work is to experimentally investigate and compare the effects of press consolidated (PC) and in-situ consolidated (ISCD) placement surfaces. In addition to the surface consolidation state as a variable, the surface fiber angle is varied and tested with various laser powers. This study was performed with a UD fiber reinforced TC1225 (LM-PAEK) material.

It is found that for PC surface there is no significant fiber angle dependency on either temperature response or fracture toughness. Whereas, the ISCD surface has a significant angle dependency on both temperature response and fracture toughness due to the higher fiber volume fraction at the placement surface. A higher temperature is observed when the fibers are along the laser direction, and the temperature is lowest when the fibers are perpendicular to the laser direction.

Mandrel peel testing is used to determine the interlaminar fracture toughness. Where, the ISCD placement surfaces exhibited higher fracture toughness than the PC placement surfaces. Fracture surface analysis of the peeled specimens show that the variation of interlaminar fracture toughness is due to the way the fiber bridging manifests due to varying fiber angle. For example, when the fiber angle is perpendicular to the laser direction the crack propagates outside the crack zone, thus, increasing the apparent fracture toughness. Though a partial process window is found, further research is required to finalize the process window.

Assessment committee |

chair Signature d.d. |

|

| Prof. Dr. Ing. B. Rosic Dr. M.I. Abdul Rasheed Ir. T. J. Asijee Dr. Ir. W.J.B. Grouve Dr. E. Kramer |

(chair) (supervisor) (supervisor) (external member) (external member) |

|