Colloquium announcement

Faculty of Engineering Technology

Department Applied Mechanics & Data Analysis (MS3)

Master programme Mechanical Engineering

As part of his / her master assignment

Baten, M.B. (Mats)

will hold a speech entitled:

Characterizing the reflective properties of composite tape for the laser-assisted fiber placement process

| Date | 20-12-2023 |

| Time | 09:00 |

| Room | OH210 |

Summary

In the pursuit of sustainable, high-performance and lightweight components for mobility sectors such as aerospace, the use of continuous fiber reinforced thermoplastic composites has seen much development in recent years. The thermoplastic polymer has the advantage of being able to melt and solidify repeatedly, allowing for automated manufacturing processes such as laser-assisted fiber placement (LAFP). During LAFP, composite tapes are melted by a high-powered laser and fused to the preceding layer or substrate under a deformable compaction roller. In-situ consolidation of the composite tapes during the LAFP process could eliminate the need for post-processing steps involving an autoclave, and can therefore be considered as a single step manufacturing process.

The quality and consistency of the consolidation of the material under the roller are strongly dependent on both processing temperature and thermal history of the material. Currently, cost- and time intensive experimental characterization is used to determine the ideal processing windows in terms of processing parameters. Predictive modelling is therefore crucial to understand the underlying mechanics of the process and to reduce the process setup by moving necessary experimentation to simulation.

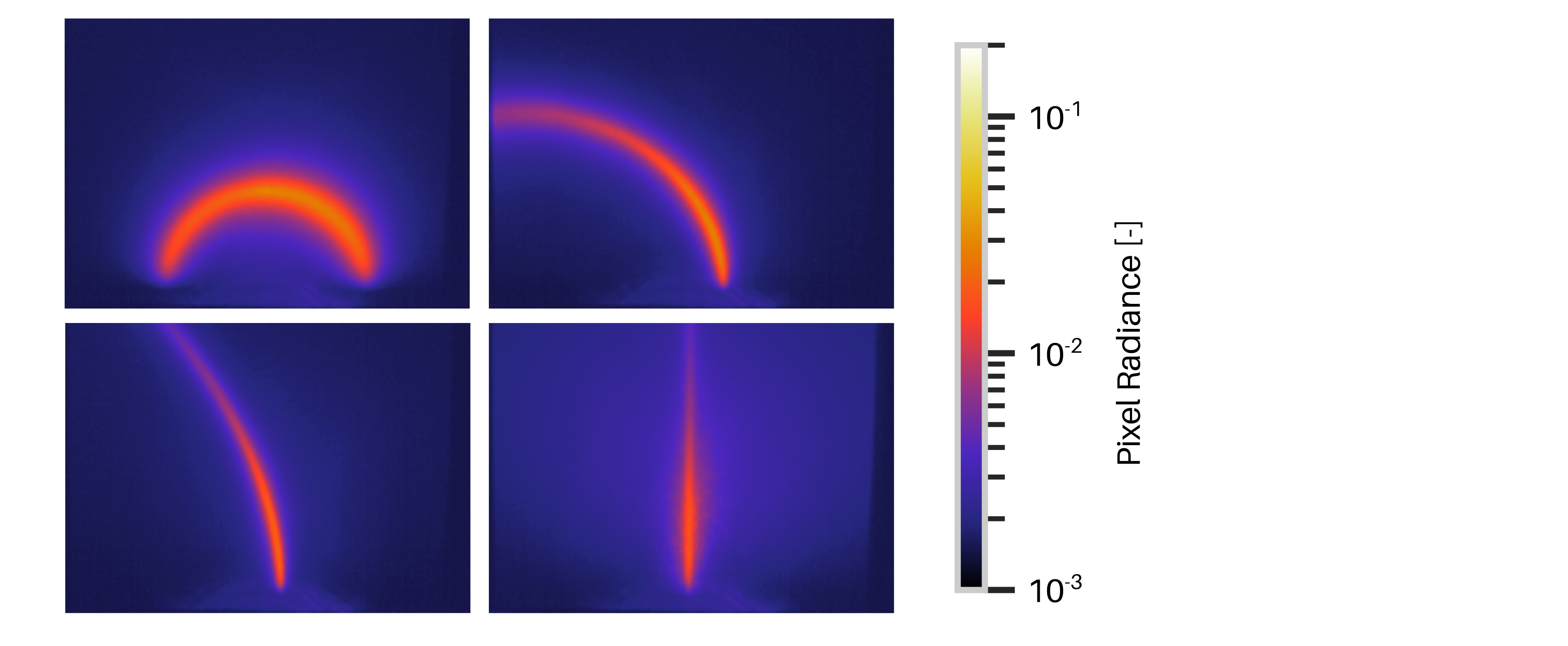

Heat is generated at the melt zone partly by irradiation of the tape by the laser, and radiation due to the reflection of the laser on the tape from the substrate. Numerical models estimate the temperature at the melt zone from the direct and reflected rays using extensive calculations based on the ray-tracing approach. To increase the accuracy of models using this method, reflective behavior of the composite tapes should be taken into account. This research aims to take a quantitative approach to the characterization of the reflective behavior of the composite tapes. The scattering patterns of the composite tapes as a function of different fiber orientations and materials were obtained using an experimental setup.

The intensity distribution of the reflected patterns have been further characterized using intuitive parameters, enabling analysis of the patterns as a function of tape. To verify the existing optical models, an image analysis tool has been developed to determine the bi-directional reflection distribution function of the tape and fit the associated parameters to the obtained data. This study has found that tapes using different materials have distinct reflection distribution parameters. Using the optical model these parameters have been approximated and can thereafter be implemented in the predictive modelling of the LAFP process.

Assessment committee |

chair Signature d.d. |

|

| Dr. Ir. R. Aarts Dr. M.I. Abdul Rasheed Ir. T.J. Asijee Dr. Ir. W.J.B. Grouve |

(chair) (supervisor) (supervisor) (external member) |

|